The seawater challenge

Seawater is a neutral chloride solution with a chloride level between 18,000 to 30,000 ppm. It can be a very challenging environment for materials used in heat exchangers where it can cause localized pitting and crevice corrosion as well as stress corrosion cracking (SCC). A further issue can be the temperature dependent formation of biofilms that further affect performance. Generally, typical stainless steel grades such as 316L are not up to the seawater challenge, and there is a tendency to use titanium alloys that are usually very good in this type of environment. But this represents a significant leap in cost, which is why Ultra 654 SMO can offer an interesting intermediate solution for heat exchangers.About Ultra 654 SMO

Ultra 654 SMO has an austenitic structure and is suitable for use over a wide temperature range where it offers very good resistance to uniform corrosion, exceptionally good resistance to pitting and crevice corrosion (PRE 28 to 56) and very good resistance to SCC. Its corrosion resistance in chloride environments is higher than nickel-alloy 625 and similar to C-276. In addition, Ultra 654 SMO offers excellent formability, good weldability and is non-magnetic. Its high mechanical strength combined with good elongation is ideal for the design of strong and lightweight heat exchangers.| Steel grade | EN | UNS | C | Cr | Ni | Mo | N | Other |

|---|---|---|---|---|---|---|---|---|

| 316L | 1.4404 | S31603 | 0.02 | 17.2 | 10.1 | 2.1 | - | - |

| DX 2205 | 1.4462 | S32205 | 0.02 | 22.4 | 5.7 | 3.1 | 0.17 | - |

| Ultra 904L | 1.4539 | N08904 | 0.01 | 19.8 | 24.2 | 4.3 | - | 1.4Cu |

| Ultra 254 SMO | 1.4547 | S31254 | 0.010 | 20 | 18 | 6.1 | 0.2 | Cu |

| Ultra 654 SMO | 1.4652 | S32654 |

|

24 | 22 | 7.3 | 0.5 | 3.5Mn, Cu |

| Alloy 625 | 2.4856 | N06625 | 0.030 | 22 | Min 58 | 9 | - | 3.5 Nb+Ta |

| Alloy C-276 | 2.4819 | N10276 | 0.010 | 16 | Min 52 | 16 | - | 3.5W, 2.5Co |

| Titanium Gr. 4 | 3.7065 | R50700 | 0.080 | - | - | - | 0.05 | O, Fe, H |

| Steel grade | Price indication ILLUSTRATIVE |

|---|---|

| 316L | 1 |

| 254 SMO | 3-4 |

| Ultra 654 SMO | 5-8 |

| Alloy 625 | 9-12 |

| Titanium Gr. 4 | 15-20x more |

A cost effective solution

Table 2 shows that, while Ultra 654 SMO is significantly more expensive than 316L (8 times) it is considerably more cost-effective than titanium alloy (15 to 20 times 316L). Furthermore, as shown in Table 1, Ultra 654 SMO has a lower nickel (Ni) and molybdenum (Mo) content than high alloyed grades, resulting in better price stability over time.| Steel grade | Rp.02[MPa] | Rm[MPa] | A50[%] |

|---|---|---|---|

| 316L | ≥ 170 | ≥ 485 | ≥ 40 |

| DX 2205 | ≥ 450 | ≥ 655 | ≥ 25 |

| Ultra 904L | ≥ 220 | ≥ 490 | ≥ 35 |

| Ultra 254 SMO | ≥ 300 | ≥ 650 | ≥ 40 |

| Ultra 654 SMO | ≥ 430 | ≥ 750 | ≥ 40 |

| Alloy 625 | ≥ 330 | ≥ 730 | ≥ 35 |

| Titanium Gr. 4 | ≥ 480 | ≥ 550 | ≥ 15 |

Table 3. Ultra 654 SMO offers an interesting combination of strength and formability.

Strength combined with formability

An important benefit of Ultra 654 SMO, as shown in Table 3, is that it combines both strength and significantly better formability than titanium.

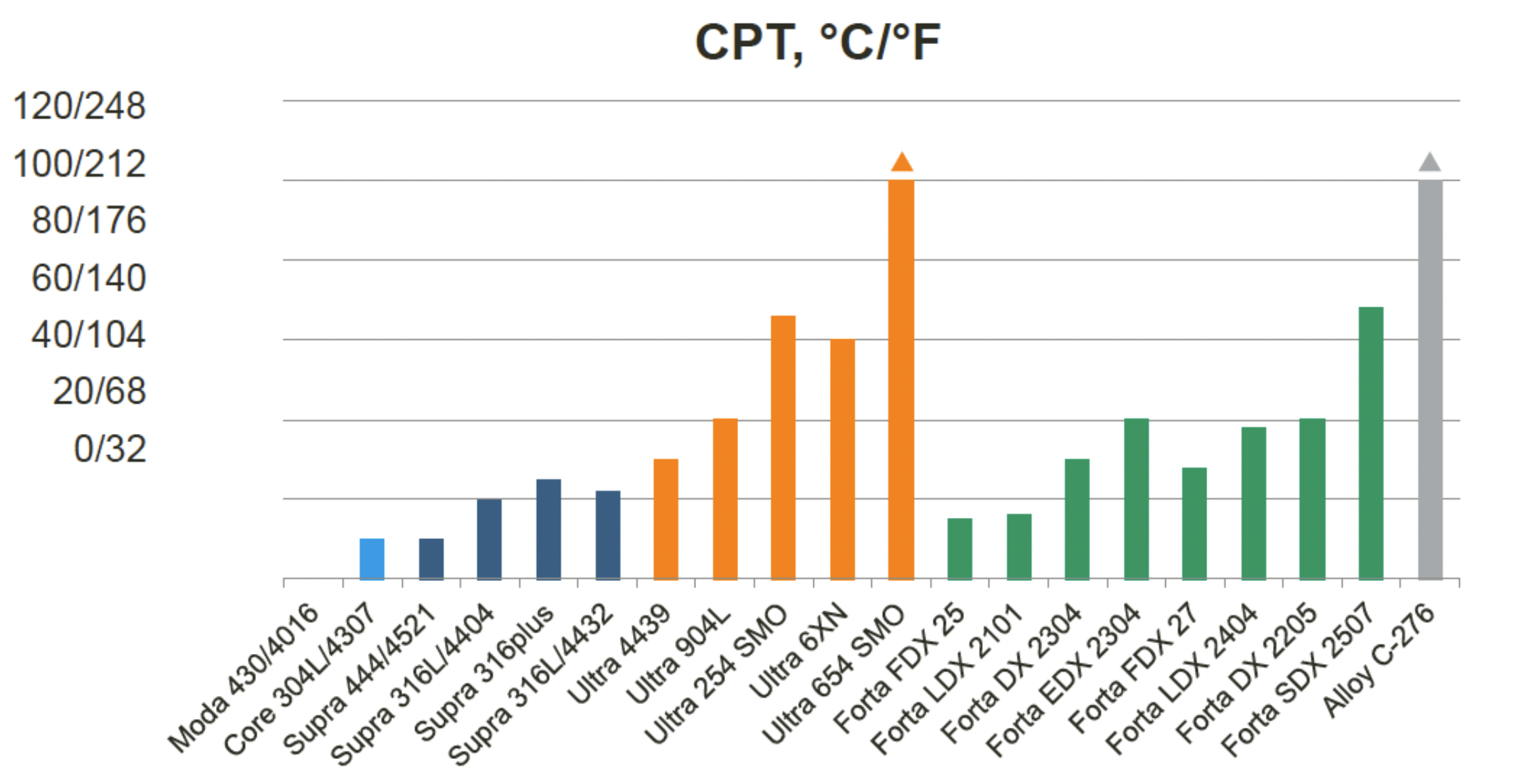

Resistance to pitting corrosion

Ultra 654 SMO offers excellent resistance to pitting corrosion under ASTM G48E testing, with a CPT comparable to Alloy C-276.

Table 4. Ultra 654 SMO offers excellent resistance to pitting corrosion, comparable to Alloy C-276.

Summary – a powerful case for Ultra 654 SMO

When considering all the properties of Ultra 654 SMO – including resistance to corrosion, high mechanical strength and good formability – it has clear potential to close the gap to titanium in demanding seawater applications such as heat exchangers.