Operators in heavy industry, chemical processing, and pulp and paper are starting to feel pressure to monitor and report on sustainability performance. Claes Tigerstrand, Senior Technical Manager explains how knowing the specific carbon footprint of our stainless steel alloys can help to identify emissions-saving opportunities.

In November 2022, Outokumpu became the first stainless steel producer in the world to start providing customers with a certificate that states the carbon footprint for the specific products they’re buying. This carbon footprint data provides industrial buyers with greater accuracy in comparing suppliers when specifying tanks, pressure vessels, pipework, heat exchangers and other process equipment.

Their engineers or consultants can also have greater confidence when calculating the carbon footprint of their own products and process equipment that contain stainless steel.

Quality, cost and availability are the currently most important purchasing factors in chemical and processing but interest in sustainability is growing. Within the next few years, carbon footprint will become more influential in procurement. Awareness of environmental data will help buyers when they need to start reporting on it.

Meeting a need for accurate data

One thing that is important to know is that there is more to carbon footprint data than meets the eye. The carbon footprint of a stainless steel product varies, depending on its content of alloying elements and recycled scrap, as well as the production route and the technology and energy supply at the steel mill.

Until now, the industry has been using average figures for carbon footprint. In Europe, this is 2.8 kg of CO2 per kg of stainless steel, yet we have achieved an average of 1.8 kg of CO2 per kg across our portfolio, which is significantly lower. That is because we use more than 90% recycled scrap in most of the products we produce. This uses less energy than processing virgin raw ores. In addition, we base production on electric arc furnace technology, powered by zero-carbon Nordic energy sources.

Our new product-specific data has provided a new level of accuracy. It takes account of the precise alloying content of the stainless steel grade, as well as the production route used to make the product.

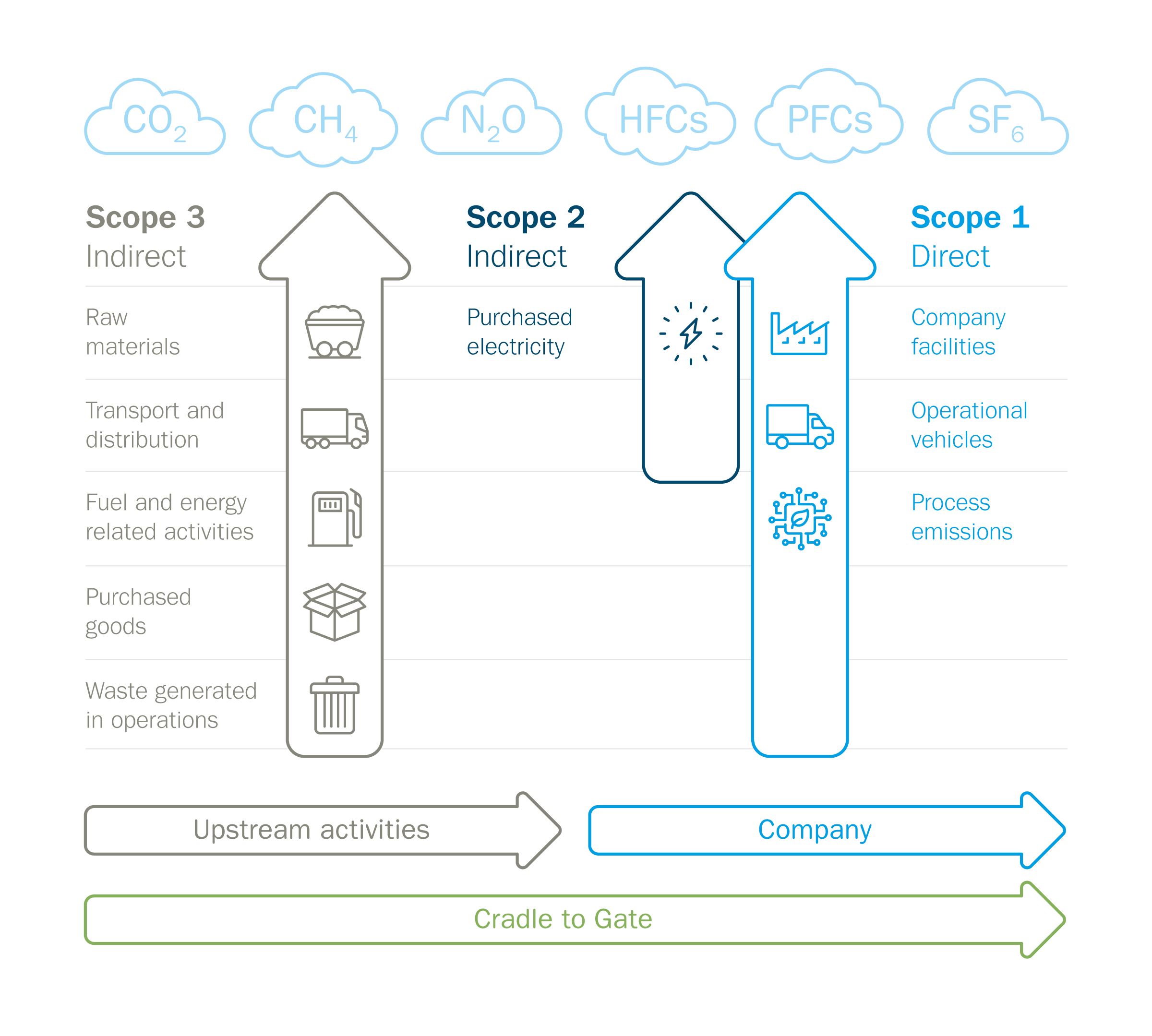

The data published on our product certificates is based on a calculation methodology that has been verified by consultancy WSP. It takes account of the environmental impact of our own production under Scopes 1 and 2 of the ISO 14040 standard. It also covers the sourcing and processing of alloying elements under Scope 3.

Impact on heavy industry and pulp and paper

Operators in heavy industrial sectors such as chemical processing tend to use standard austenitic grades, as well as higher-alloyed austenitic grades, nickel-based alloys and sometimes duplex grades. These provide enhanced corrosion resistance for process equipment and pipework.

Meanwhile, pulp and paper mills often use duplex stainless steel grades. These have a combination of high strength and corrosion resistance that makes them ideal for pressure vessels and storage tanks.

The choice of alloy depends on the corrosivity of the environment and in turn, this influences the carbon footprint. As the alloying content increases, the carbon footprint of a particular product will become higher. However, having access to the specific data relating to a product ensures that buyers get an accurate picture of what they’re buying.

Comparing data from different material suppliers

There is another important factor to consider when comparing environmental data between suppliers and different types of materials. Although carbon footprint data is published as a straightforward number, it may not be possible to directly compare data from different suppliers.

That is because the ISO 14040, ISO 14025 and ISO 21930 standard allows for some interpretation. It includes product category rules (PCR) that can be applied in different ways. For example, the allocation procedures for recycling may favour the use of one material over another. This is impacted by how emissions related to the use of either primary or secondary raw materials are treated, and how scrap generated at end-of-life is acknowledged for use in subsequent product life cycles. This is problematic as it influences carbon footprint data. It can be overcome with further development of the PCRs and allocation procedures for different types of materials.

To get a true comparison, buyers should be willing to ask detailed questions about the carbon footprint methodology used and how the PCRs have been applied. This will give them the ability to compare how the underlying data stacks up using a consistent approach.

So far, sustainability reporting has not yet become business-critical for heavy industry and the carbon footprint of processing equipment may be small over its lifetime compared with the energy needed to operate an industrial plant. Product, price and availability will continue to be the top priorities for industrial buyers in the short term.

However, sustainability will continue to increase in priority so it’s worth being aware of the data that is now becoming available, as well as best practice in its interpretation.

Storage tank calculator

The calculator allows you to calculate and compare different materials for storage tanks. It is an easy way to see and learn how your selection of steel grade affects material consumption and cost.

Open the calculator