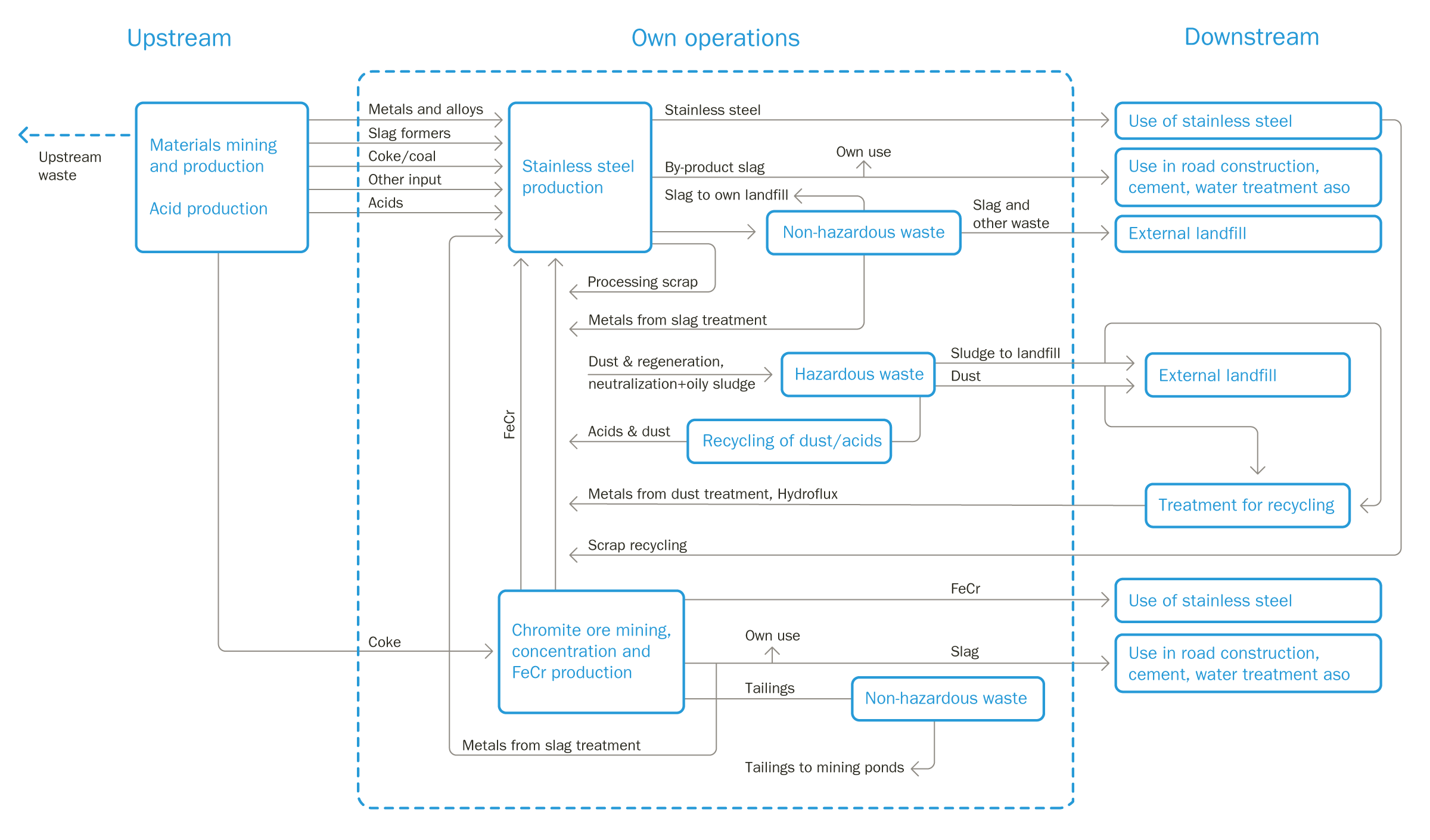

Outokumpu's ultimate target is zero-waste stainless steel production. This means that all material streams from production are studied in order to find means of fully recycling, reusing or selling them as by-products on the market. Generally, all processes are developed in a way that allows valuable metals - like iron, nickel, chromium and molybdenum - to be recovered and retrieved from material streams.

Slag and dust

Slag and dust are the main by-products of the steelmaking process. Minerals are formed as slag and hot liquid steelmaking process. Slag prevents the loss of crucial alloying elements during melting and aids in the refining stages. It is also essential in protecting the molten metal against oxidation and heat loss. Slag is by far the biggest material side stream.

Outokumpu has invested considerable research and development in methods of retrieving valuable metals from slag and dust, to reuse the metals as raw materials in the Group's melt shops. For example our melt shop in Tornio is able to commercialize a full 100% of its slag sidestreams, selling slag products to private companies and households or reutilizing it in our own processes or construction projects.

Outokumpu has also developed slag-based by-products for example for construction, neutralization purposes in industrial applications and agriculture. For example in road construction slag products replace virgin materials such as crushed stone aggregate and where its performance is actually better than that of its alternatives. A recent study by Destia showed that significant CO2-savings can be achieved by using Outokumpu's slag by-products.

Dust-filtering systems at Outokumpu catch 99% of the dust generated by production operations. All of the dust generated by the company's melt shops is recycled, with collected dust fractions that have the highest metal content being recycled directly, and the remainder of the collected dust being recycled following a metal recovery process. In the Nordic region, this residue is transported to an external facility in Sweden which recovers the metals contained in the dusts. In the UK, the in-house metal-recovery facility is on site. Over the year Outokumpu has decreased dust emissions significantly.

Waste

By paying attention to waste management and segragation techniques, we have managed to maintain about 65% of waste and by-material in the circular economy. Outokumpu has continued to increase the percentage of recycled and recovered waste. Waste from our production units is sent to appropriate treatment facilities or landfill sites that are licensed to accept such materials.