STILRIDE’s CEO, Jonas Nyvang, says: “Many people are unaware how much manufacturing contributes to the environmental impact of the products they buy. We knew that our manufacturing process had a clear environmental lead over the market-leading electric scooter from China. Therefore, we decided to quantify it.”

A new Life Cycle Assessment (LCA) was carried out by IVL, the Swedish Environment Institute. It found that the chassis materials in STILRIDE’s Sports Utility Scooter One have a carbon footprint of around 50 kg CO2 per unit. This is only one third of the 160 kg CO2 per unit for the reference scooter.

Eye-catching structural design

The key to the low carbon footprint is STILRIDE’s STILFOLD design and manufacturing technique. It uses a similar concept to origami, where paper sheets are folded in three dimensional forms. STILFOLD builds on this by using industrial robots to precisely control the folding and bending of stainless steel sheet into complex chassis components that combine eye-catching design with structural support.

This method is a major departure from traditional scooter designs that use carbon steel tube frame structures with additional bodywork and other components made from mixed plastics and rubber.

Nyvang adds:

“With STILFOLD, we are using high-strength stainless steel to create a design statement and a structure in one. The result is a simple, lightweight and corrosion-resistant chassis with fewer components – and the new LCA also shows it has a smaller environmental footprint.”

The LCA compares the materials needed to build and transport the scooter chassis. It excludes batteries, other components that are almost identical to both models, as well as the energy used during manufacture.

Lightweight stainless steel

STILRIDE chose Outokumpu’s Forta 301 temper rolled stainless steel as the basis of its design. Temper rolling means that the material has high mechanical strength compared with other steels. This makes it possible to achieve the same load-carrying capability with less material, making it lightweight.

Through the STILFOLD design, the chassis of the Sports Utility Scooter weighs only 15 kg of the total 80 kg weight of the bike. This compares with a 45 kg chassis and a 110 kg overall weight for a typical scooter.

Nyvang adds:

“Lightweighting has multiple advantages. The most noticeable for riders is better acceleration and ride quality. However, it also improves the range and preserves battery life as the 30 kg saving on the weight of the scooter plus its rider will reduce energy consumption by a respectable 5 %.

“It also creates a new opportunity for us to develop a scooter for city deliveries and logistics fleets that can carry 30 kg more payload than other bikes, something we’re looking to develop in the future.”

The chassis also has fewer components than a conventional scooter (around 20 versus 120). That makes for simpler manufacturing and logistics and less sourcing from multiple different manufacturers. It also makes maintenance more straightforward for riders.

STILRIDE founders CEO Jonas Nyvang and Industrial designer Tue Beijer.

Recycling for low carbon footprint

Recycling is another aspect of Outokumpu’s stainless steel sheet that STILRIDE is using to limit the environmental impact of its manufacture.

According to a study by Yale University, 85 % of stainless steel is recovered as scrap metal at the end of its life, before processing and remelting without affecting quality. However, with global demand increasing, this only covers 44% of the material needed today.

Recycling makes a huge difference to carbon footprint of steel products. Compared with stainless steel made from virgin iron ore, every tonne of recycled austenitic scrap used in the production of stainless steel saves 4.3 tonnes of CO2 emissions.

Camilla Kaplin, Outokumpu’s Senior Manager - Environment said:

“At Outokumpu, we have the lowest carbon footprint in the stainless steel industry. We base more than 90 % of our production on recycled materials and our Tornio mill in Finland is home to Europe’s largest recycling center. We also purchase low-carbon electricity and use energy efficiency programs to minimize our carbon footprint.

“We publish a set of Environmental Product Declarations (EPDs) on our website so that our customers can compare our environmental performance with other producers. They can also use our data to calculate the environmental impact of their own products and services, with IVL’s lifecycle assessment of STILRIDE’s chassis as an example.

“Typically the data in an EPD is valid only for a certain period of time, usually up to 5 years, so as we update and revise our EPDs, they will reflect our ongoing efforts to decrease our footprint. Last year we renewed our CO2 reduction target, and set a new, even more ambitious long-term goal.

“We intend to decrease our carbon footprint by 30 % between now and 2030, which corresponds to a reduction of 42 % compared to our baseline years 2014-2016. To achieve this we are initiating a number of projects, from switching to low-carbon fuels to investing in new low-emission cargo ships to transport products between Tornio and our distribution hub at Terneuzen in the Netherlands.”

LCA analysis over 10 years

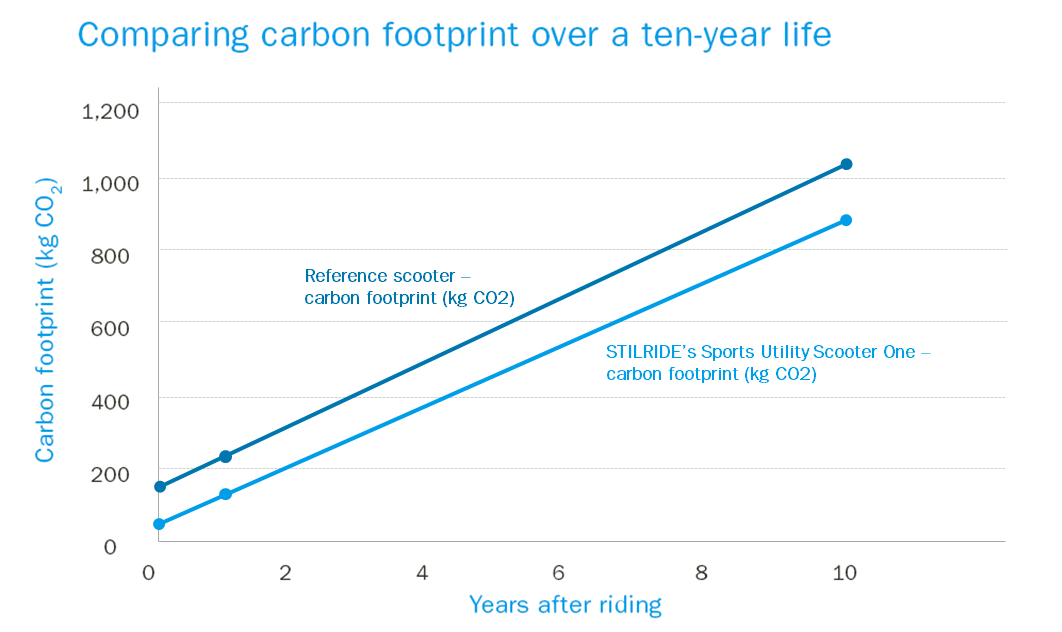

While STILRIDE’s scooter has a low-emission advantage when it is new, IVL’s life cycle analysis shows that it maintains this lead. True LCAs must reflect the full lifetime so for the two scooters, this must include the energy used to charge up the batteries for driving. Therefore, IVL calculated energy consumption during one and ten years of use, with annual mileage of 5,800 km for a typical European rider.

Over time, the emissions from riding become the lion’s share of the scooters’ emissions.

On day one, the reference scooter’s footprint is more than three times STILRIDE’s, at 160 versus 50 kg CO2. After a year, these grow to 245 versus 140 kg CO2 and after a full ten years, the reference scooter’s footprint is ten percent higher at 1,030 versus 890 kg CO2. Therefore, at the end of the ten-year life, the reference scooter may have narrowed the gap in percentage terms but STILRIDE has increased its numerical lead, thanks to the advantage of lightweight design.

Table 1. LCA analysis of carbon footprint between STILRIDE's Sports Utility Scooter One and a reference scooter.

|

|

Reference scooter – carbon footprint | STILRIDE’s Sports Utility Scooter One – carbon footprint |

|---|---|---|

| New | 160 kg CO2 | 50 kg CO2 |

| After one year riding | 245 kg CO2 | 140 kg CO2 |

| After ten years riding | 1,030 kg CO2 | 890 kg CO2 |

Figure1. LCA analysis of carbon footprint between STILRIDE's Sports Utility Scooter One and a reference scooter.

Commenting on this, Nyvang says:

“Over ten years, both scooters consume a similar amount of energy for riding, meaning that at a glance, it looks like the competition narrows our environmental lead – but they can never catch up.

“Being a Swedish company, we also wanted to check the impact of our energy mix compared with the European average. Sweden is rich in clean energy such as hydro-power, therefore our electric power grid has an unusually low carbon footprint. When we looked at the impact of this energy mix over a ten year life, we found that in Sweden, the typical rider for the reference scooter would have climate change impact 80% higher than a STILRIDE customer. It’s an interesting point as it highlights how renewable energy influences the overall impact of driving any type of electric vehicle.”

Sustainability benefits beyond 10 years

There is one final sustainability advantage that STILRIDE has over its competitors: corrosion resistance.

Stainless steel contains metal alloying elements that react with air to form a microscopic passive layer. This impenetrable barrier prevents the iron from oxidizing into rust and is self-healing as it reforms immediately when scratched. This does not exist in the carbon steel used to build most scooter chassis, making them susceptible to rusting and limiting their life.

As a result, the standard scooter frame will eventually be eaten away while STILRIDE’s chassis will remain as good as new. In the long term riders will be able to exchange motors, batteries, lights and accessories while keeping the original sheet metal structure.

Reflecting on this long-term thinking, Kaplin says: “Producing stainless steel is energy-intensive as we need to melt steel but it can be seen as an investment in energy. Yale University’s study found that products made out of stainless steel have an average lifespan of 20 years, and often much longer. One famous example is the spire of the Chrysler Building in New York, which has remained pristine ever since it was built in the 1920s.”

It’s impossible to give an accurate estimate of how long STILRIDE’s scooters will last (and the same goes for the reference scooter). That’s because that will depend on environmental factors, such as humidity and proximity to the sea, which affects the corrosivity of the air.

Nyvang concludes: “Ultimately, the Sports Utility Scooter One is not just a scooter. It is also a demonstration of STILFOLD as a new approach to engineer structures that combine strength and beauty, lighter weight as well as having a significant climate advantage.

“We commissioned the life cycle assessment from IVL so that we can quantify the carbon footprint savings. But because we don’t yet know exactly how long the chassis will last, it could be just the tip of the iceberg in terms of its whole-life carbon footprint advantage.”

STILRIDE’s Sports Utility Scooter One will be going into production during 2022 and more than 90,000 potential riders have already registered an interest.

STILRIDE’s Sports Utility Scooter One