Aluminum and low-alloy steels are the traditional choice for battery housings. But these materials can be restrictive in terms of both design and manufacturing flexibility and have limited safety potential. Stainless steels and their associated construction and manufacturing concepts can help address these challenges. Furthermore, stainless steel is a perfect fit with the overall sustainability concept that is driving the introduction of EVs. In fact, stainless steel is the leading material for sustainability as it is produced using more than 85 percent recycled scrap content, and it is 100 percent recyclable at the end of its long service life.

Outokumpu Forta H-Series – developed for safety-critical vehicle structures

An interesting option for battery housings is Forta H-Series, a new generation of fully-austenitic stainless steel developed for safety-critical structural vehicle components. With a yield strength of Rp0.2 ≥ 1000 MPa, in combination with high elongation to fracture, it opens up new opportunities in lightweight engineering and design. Forta H-Series also has very high energy absorption in the event of an impact with the added benefit of heat resistance.

Heat resistance in case of fire

Stainless steel can save weight and improve the crash resistance of EV battery housings. Crucially, it also provides the heat resistance essential to ensure passenger safety in the event of a fire. The general requirement is to contain a fire for a period of up to 10 minutes to enable the safe evacuation of vehicle occupants. The aluminum material typically used for first- generation battery compartments will fail in just five minutes at 600 °C. In contrast, tests show that austenitic stainless steels, such as Forta H-Series, will survive a temperature up to 1250 °C for over 10 minutes with only a small deflection. Outokumpu’s scope is not limited only to austenitic grades. With its Therma range it also offers a selection of ferritic grades developed specifically to provide outstanding properties in the highest operating temperatures.

Outstanding deep-drawing properties

The combination of high strength and enormous ductility gives austenitic stainless steels outstanding deep-drawing properties. These facilitate complex forms and contribute directly to component stiffness. To see how this is applied to battery housings it is useful to look at some possible design scenarios.

Battery floor shell

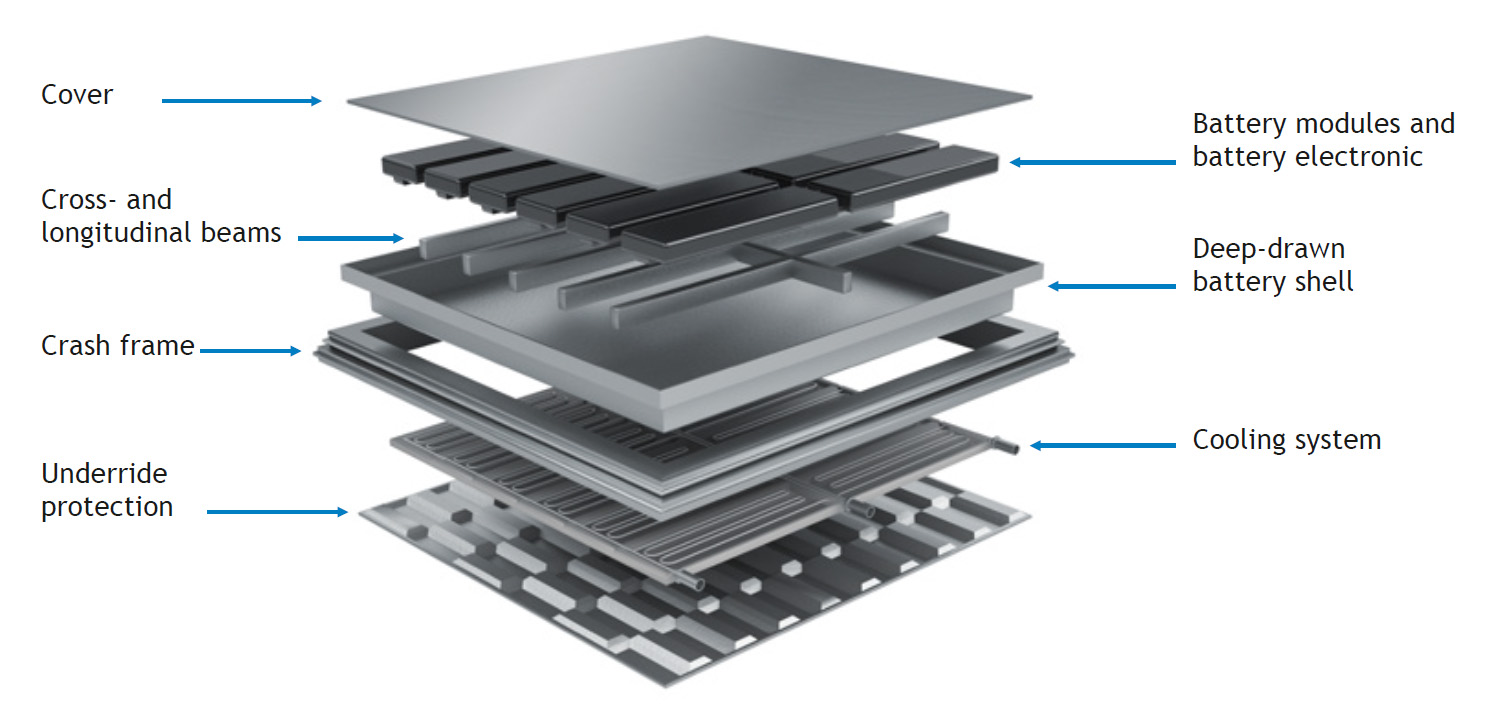

The battery housing must offer the largest possible space envelope for the battery modules, while meeting requirements for sealing and mechanical loading. A geometrically simple battery housing can be designed using stainless steels as a deep-drawn shell. The advantage of this approach lies in its sealing and less elaborate manufacture compared to the use of fabricated structures made from low-alloyed steels or extruded aluminum profiles. Furthermore, deep-drawn battery floor shells save considerable packaging space. There is also no need for production steps involving welding in the battery “clean room”. This eliminates thermal distortion and reduces cleaning requirements, which lowers production costs. Figure 1 shows a diagram of all the battery housing components.

Figure 1. Stainless steel concept for an EV battery compartment.

Thermal management

Li-ion modules for EVs generate a significant amount of heat inside the sealed battery housing. In the event of damage, the liquid coolant must not come into direct contact with the modules. The ideal solution is passive cooling, which presents additional advantages in production and assembly, as well as subsequent accessibility. Temperatures above 45 °C can cause battery damage. Equally, charging capacity and vehicle range decrease at temperatures below −5 °C, so indirect system heating might be needed in winter. Functional thermal management guarantees high battery performance. This is enhanced by stainless-steel sheet that offers thermal advantages over extruded profile and die-cast semi-finished products.

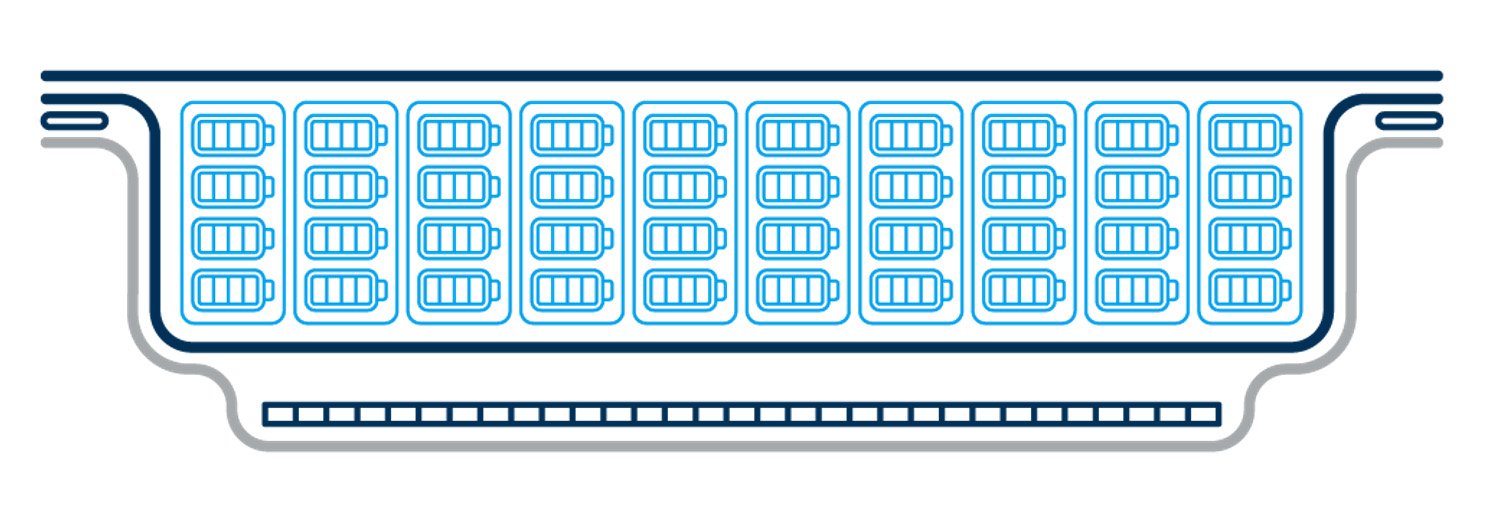

Figure 2 illustrates the principle of a dual-wall shell, where the inner shell contains the battery modules and the outer shell the cooling and/or heating circuit. Using an inner shell made from thin ferritic stainless steel and a thicker outer shell made from austenitic stainless steel takes advantage of the different material properties.

Figure 2. Dual-wall shell concept with integrated thermal management.

Crash frame

High energy absorption is the key property of the crash frame, which is positioned between the battery shell and rocker panels. This configuration must form a coordinated system in the event of side impact. Alongside geometric design, material selection is a crucial factor. In addition to high residual ductility, the component must have very high strength.

Using Forta H-Series with its TWIP (Twinning Induced Plasticity) strengthening mechanism, it is possible to produce complex shapes as roll-formed profiles, with high stiffness due to the complexity of their form. The forming energy applied also causes significant material hardening, resulting in extremely high strength.

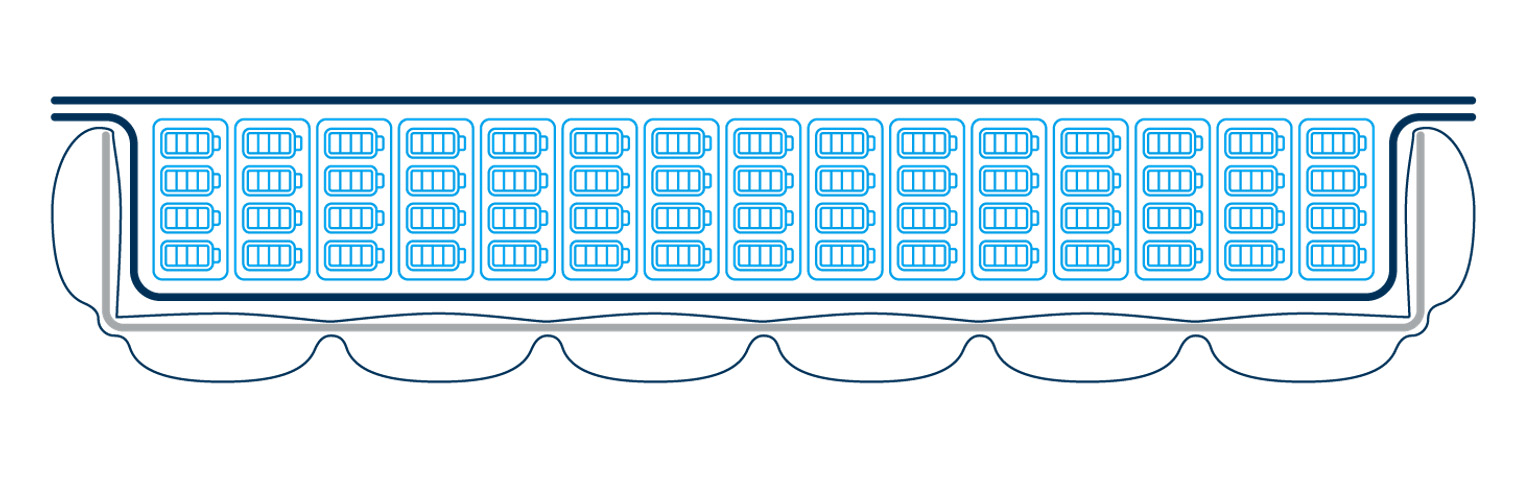

The ideal scenario is a twin chamber, with the profile facing the rocker panel absorbing the energy and the inside profile generating high intrusion resistance.

Figure 3. Crash frame in a form of a high-strength pillow-plate absorber.

An alternative crash frame concept is internal high-pressure forming using an active fluid medium for producing extremely stiff pillow-plate absorbers, see Figure 3. Again, the deformation energy of the process produces significant material hardening, while the geometry delivers high stiffness. Just like the two-chamber principle, an outward-facing energy-absorption area can be defined using a section of thin exterior sheet. The space between the two areas can be used for other applications such as the thermal management system.

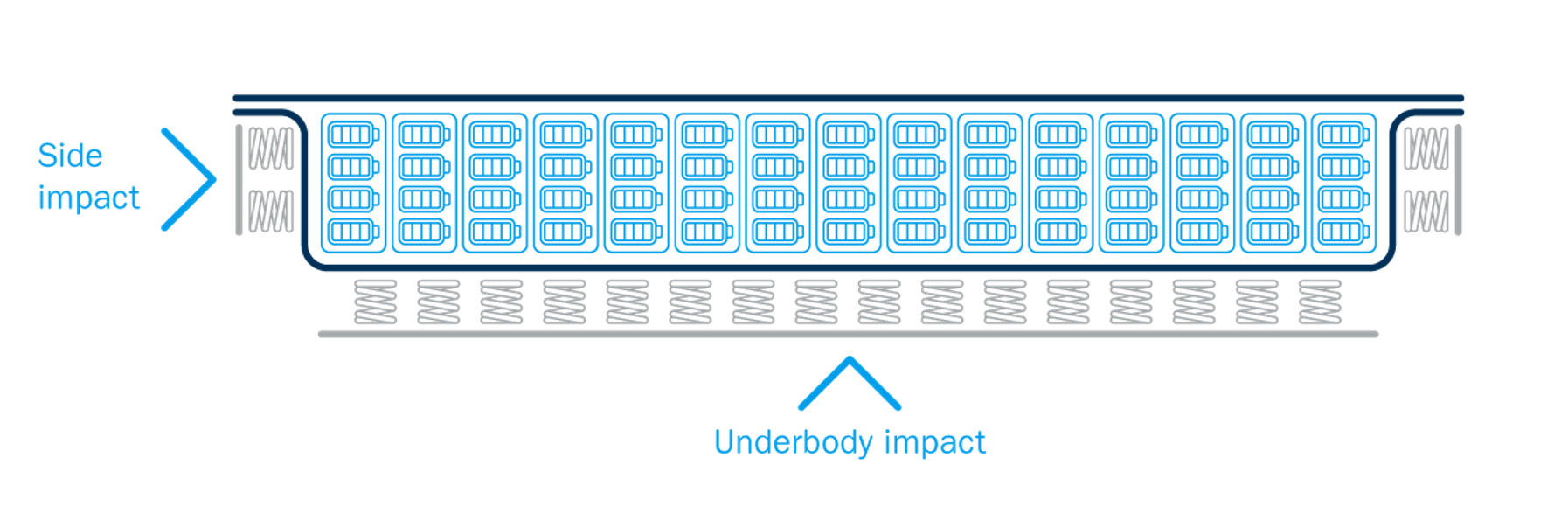

Under-ride protection

The under-ride guard supplements the battery housing to protect the thermal management system and modules against intrusion from the underfloor area. It requires a careful balance of energy absorption capacity and high resistance to intrusion. Stiffness is a vital issue, which can be positively influenced by corrugations. This area is also subject to high corrosive load so stainless steel is particularly beneficial.

One approach is to use mechanical compression springs, cold-formed from stainless steel, embedded in a double floor, as shown in Figure 4. This construction method causes the underfloor guard to glance off, reducing impact forces. Also other stainless steel systems following the behaviour of springs could be used beneficially – such as corrugated sheet metals or bend-formed structures.

Figure 4. Schematic view of the double-floor spring design.

Stainless steel can further the acceptance of electric vehicles

Stainless steels offer a wide range of properties that can address the complex issues associated with the design and manufacture of battery housings for electric vehicles. This makes it possible to create innovative concepts that combine fire resistance, crash safety and thermal management. For automotive manufacturers and their customers this will have a positive effect on safety, performance and range, helping to further increase the general acceptance of EVs.

Are you interested to learn more?

Our Lead Technical Manager, Stefan Lindner, presented Outokumpu's broad portfolio of stainless steels for battery housings during the Mobility webinar series. The recording is available on our website, please see the second webinar with the title: "How to master the challenges of e-mobility with stainless steel".