Reducing the risks in the operations is a constant work in progress and it is important that everyone is aware of the risks present. In this section we focus on the general, major risks within the site. But it is also important that you take part of the risks that concern your place of work or task. Talk with your nearest manager, colleague, contact person or safety representative.

Traffic and transports

The traffic is many times very lively in the area and the roads are trafficked by large trucks that handle heavy and bulky goods. The load can be projecting, but not provided with warning flags or lamps. Pay, therefore, extra attention as a fellow road user as truck drivers have, in many cases, limited views.

As a pedestrian or cyclist it is important that you stay on the intended walking and cycling paths to avoid the risks associated with heavy traffic. Give the traffic precedence if you do not clearly have eye contact with drivers before you cross roads.

It is not allowed to drive a car or use bicycle or walk and at the same time use a mobile phone. This applies regardless of whether headset is used.

Crossings at the busiest railway tracks have light and sound signals, but there are also a number of places where road and rail crossings are only marked with signs.

The rail traffic always has precedence, so respect the signals and signs whether you are pedestrians, cyclists or vehicle driver.

Liquid steel and slag

Within the Steel Mills' production area there are risks connected with the molten liquid steel. The steel is processed and moved within the production premises and large parts of the premises are forbidden to tread during operation in order to minimize the risk of personal injury.

Moisture that can enter into the melt and be vaporized expands rapidly and can cause explosions. Therefore, stay out of the vicinity of the hot steel even during maintenance stop.

Explosions can also occur at the tapping of liquid slag in the slag yard. Therefore, for stays on or in the vicinity of the slag yard approval is required from the area's responsible manager.

There is a great danger when remaining in the vicinity of the towing vehicle when the slag is being transported to the slag yard. There may be a hole in the slag wagon, which means a risk of explosion. There is also a major risk of a tire bursting. Therefore, it is not permitted to be in the vicinity of the towing vehicle or to park the vehicle along the so called "Slag path/Slaggvägen".

Chemicals

Handling chemicals always involves risks and all handling of chemicals shall be risk assessed to ensure that adequate measures for protection are taken to protect from ill health and accidents. Protective measures can be, for example, extractor fan, tools or personal protective equipment. If you are unsure how to handle a chemical, ask your nearest manager or experienced colleague. Our chemical management system IChemistry, where you can find information about the product you handle, is on the intranet.

Contractors shall, firstly, use our stored chemicals. If there is a need for other products in, for example, a project, account shall be taken to this in connection with the coordination so that there are no risks for the surrounding staff or environment. Applied for our preferred suppliers is to, with the quarterly reconciliations, declare which products are used and how they handle the risks.

Avesta Works is also a so-called SEVESO facility because of the large amounts of dangerous chemicals (hydrofluoric acid and LPG) used in the process. Hydrofluoric acid and LPG are described in more detail below.

Hydrofluoric acid

Pickling of steel strips at KBR uses, among other things, hydrofluoric acid. The acid is extremely dangerous as it, when in contact with skin or inhalation, eats through the tissues and can cause cardiac arrest. Even very small quantities in diluted form can cause serious injury.

Everyone who works in the facility where the Hydrofluoric acid is handled shall undergo Hexafluorine training and carry the Pink card with information to healthcare in the event of injury. Hexafluorine is a first aid preparation that neutralizes the acid before it enters through the skin.

Special authorization (Work permit) is required for working at equipment that contains/has contained acid.

At the slightest suspicion of…

Skin contact - Spray directly, as well as continuously with Hexafluorine until you receive medical care. Remove contaminated clothing.

Eye contact - Flush continuously with Hexafluorine until you receive medical care.

Inhalation - Make sure to get fresh air and contact ambulance for rapid transport to doctor.

Liquefied petroleum gas

Liquefied petroleum gas (LPG) is a flammable gas used in the processes within Steel mills and Hot strips. LPG is unloaded at the Hot strip building and is transported in lines to the Steel mill. Work on the LPG facility requires special work permits issued by the LPG manager for Avesta Works.

Cranes

Cranes are one of the most frequently used work tools at Avesta Works and is also involved in many of the incidents and accidents that occur. There are often large and heavy loads being handled and it is therefore important that those driving, maintaining or being around traverses are attentive and have respect for the powers of the traverse and its load. Falling objects or loads, as well as crushing hazards are some of the dangers related to crane operating. In some areas there are also automatic cranes that may start without warning.

- Am I far enough away from the crane load?

- Has daily checks been made on the crane?

- Do I have relevant training, driving permit and experience of the crane?

- Is the crane suitable for the load I will be lifting?

- Is the equipment sufficiently safe before I begin work on or with it?

As an operator it is important to be alert to the work with cranes and therefore you must not talk on a cell phone while you are driving.

Being on and doing maintenance work on crane/traverse:

Being on a crane/crane path can be extremely risky. To be allowed to walk on a crane path requires that the crane operator is informed and that the crane is stopped. Lockout/Tagout, brake stops with hanging strips and barriers are part of the measures required in order to be able to work safely on cranes.

Falling or spattering material

The coils with finished plate are held together by one or more packaging strips. If the packaging strip releases, the strip end can burst out. There is also a risk that the strip will coil up like a spring due to the inherent power. Remember to keep sufficient distance to the coils.

Scrap is handled in the Scrapyard. The scrap is stored in piles and can start to move, for example, as a result of the wind.

In the Hot continuous grinding scales can burst from hot slabs with risk of damage to the eyes. At the Hot rolling there are plate pieces that risk loosening with certain rolling, pay attention to the yellow blinking light that warns when rolling is in progress.

Hot surfaces and material

Since the manufacturing process means working with heating the material, there is a risk of coming into contact with hot surfaces. Both in the handling of process equipment and the material attention should be paid to the temperature to avoid burns. Follow safe working methods and use required personal protective equipment.

Crushing and cutting injuries

Steel strips and parts of these are sharp and can have edge damage. Use the right tools and the intended personal protective equipment when handling these. Even in the handling of packaging strips there is a risk of cutting injuries. Scrap or metal pieces that fall or spatter in the process are also dangerous.

Equipment that rotates or is compressed always involves a risk of crushing injuries or retraction. Make sure to secure a equipment before you begin working on it. (See section for Lockout/Tagout)

You should never disable a protection system by, for example, removing a fixed fence or bypassing a protective device.

The usage of fixed blade knives or other cutting tools with fixed and unprotected blades can cause serious injuries. The Outokumpu Health and Safety Standard Cutting Tools describes which tools that are allowed to use.

The usage of jewelry, watches, necklace etc. increases the risk of getting caught in different objects. There are restrictions for usage of these in production areas, workshops and laboratories. The Outokumpu Health and Safety Standard Jewelry Standard describes the restrictions.

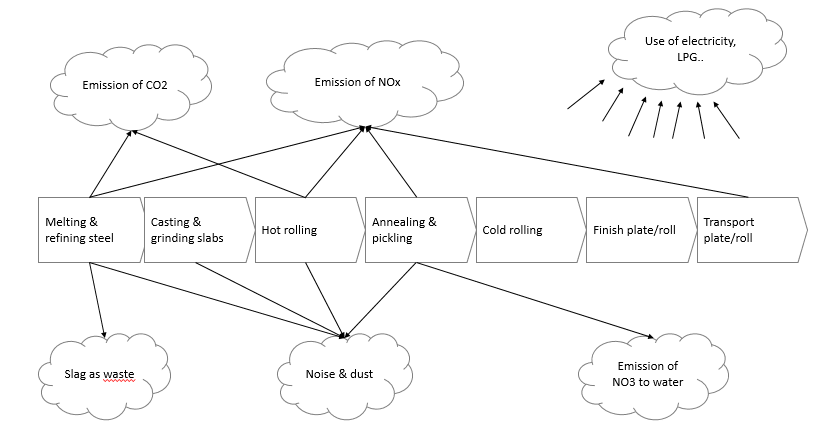

Environment and Energy

Avesta Works' production means that waste and emissions are also produced. For several of these there are requirements set for how much the operations may emit and affect the surrounding environment.

Energy

Availability of energy is one of Avesta Works most important resources and also their largest variable cost. Avesta Works uses 700 GWh (700 million kWh) energy annually. Avesta Works uses as much energy as 35,000 heated houses or energy conversion from 100 new wind plants each year.

- Follow instructions/PM templates and let us know if it does not describe the present work approach

- Follow procedures for waste management and recycling

- Environmental critical equipment - set training requirements for the task

- If you detect discrepancies or risks - notify your manager/contact person

- Ease up on the accelerator and turn off the lights (empty rooms are dark rooms)

- Follow the instructions and procedures for reduced energy consumption, such as

- Control of furnaces

- Shutdown procedures

Online safety course and knowledge test

To receive your certificate, read through the following sections and then take the knowledge test:

3. Awareness of the risks