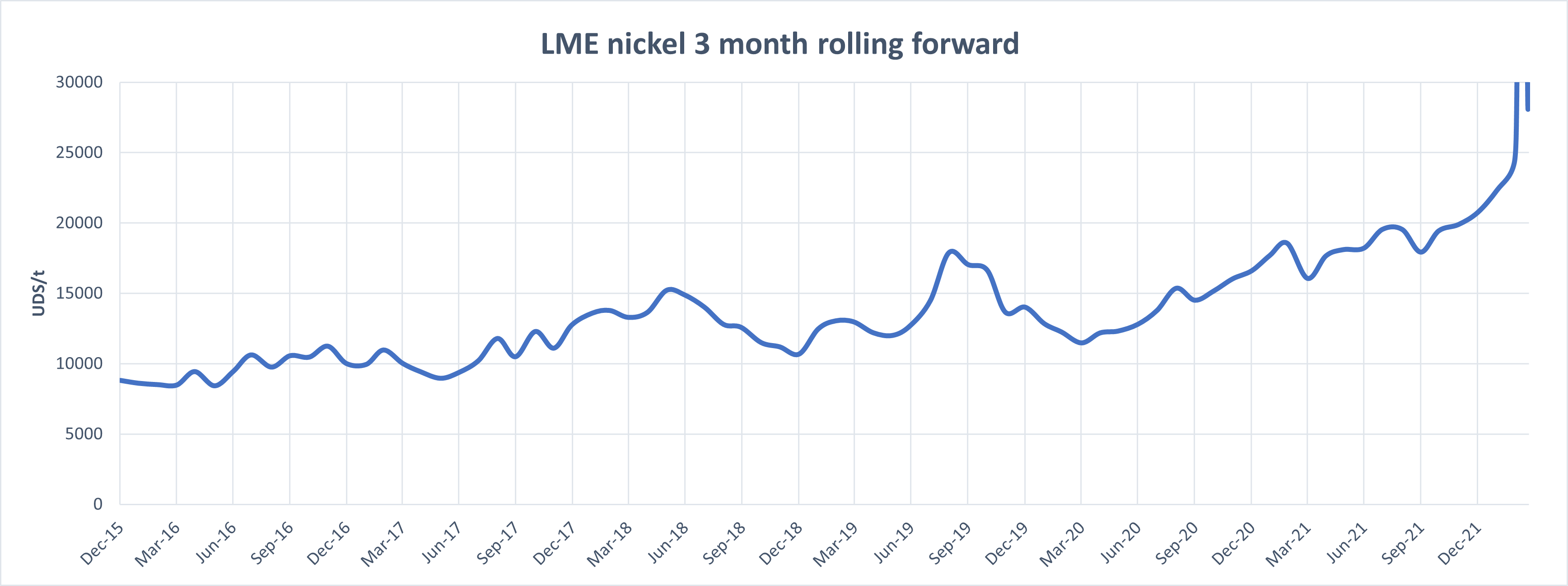

Figure 1: Nickel prices can fluctuate considerably

Stainless steel relies on chromium (Cr) as the crucial alloying element that provides its basic corrosion resistance. But it is nickel (Ni) that has been crucial in stainless steel becoming a truly versatile material. It enhances key properties such as formability, weldability and ductility. That is why for around a century, nickel-alloyed austenitic grades such as Core 304 (EN 1.4301) and ‘acid-proof’ Supra 316L (EN 1.4404) have been regarded as the “go-to” solutions for a wide variety of applications. Their typical uses include household appliances and consumer goods, kitchen equipment, indoor and outdoor cladding, handrails and window frames, food and beverage processing equipment, storage tanks, heat exchangers, flanges and valves.

However, for all the benefits that nickel brings as an alloying element, it also comes with significant challenges in terms of a price that is both high and extremely volatile, as illustrated in Figure 1. Most recently, current geopolitical concerns have seen nickel prices rise by a factor of around 2.5 times in less than a year. In fact, while nickel only makes up 8 to 10% of the total mass of Core 304 or Supra 316L, it can be responsible for more than 65% of the cost. For that reason, you might find it interesting to look at alternative low-nickel, or no-nickel, stainless steel grades. These can eliminate the volatile pricing associated with nickel, but with no loss of performance.

Table 1: Low or no nickel alternatives to 304 and 316L

| Type | ASTM | EN | Nickel content |

|---|---|---|---|

| Core 304/304L | 304 | 1.4301 | min 8.0% |

| Supra 316L | 316L | 1.4404 | min 10.0% |

| Forta LDX 2101 | S32101 | 1.4162 | min 1.35% |

| Core 4509 | S43940/S43932 | 1.4509 | not alloyed |

| Supra 4521 | 444 | 1.4521 | not alloyed |

Lean duplex stainless steels with low nickel content

As an alternative, lean duplex stainless steels such as Forta LDX 2101 (EN 1.4162) combine many of the beneficial properties of ferritic and austenitic stainless steels, including high mechanical strength and corrosion resistance. It has a low nickel content of just 1.5% and is ideally suited for storage tanks, household heaters, structural components for bridges or rebar for concrete structures, pulp and paper machinery and flanges and valves. It is possible to select other duplex grades with very high corrosion resistances and strengths, but it may be important to make allowances for the latter in forming processes.

Ferritic stainless steels with no nickel

In some applications, it might be possible to substitute an austenitic grade with a ferritic grade such as Core 4509. This is a nickel-free 17% chromium grade with good corrosion resistance and high-temperature strength that was originally designed for exhaust systems. Its good formability and weldability make it a suitable replacement for Core 304L in indoor cladding, restaurant equipment and appliances, tubes and heat exchangers.

Similarly, Supra 316L can be substituted by Supra 4521. This is a nickel-free molybdenum-alloyed ferritic stainless steel with very good corrosion resistance, good cold formability and high strength. It allows for thinner walls in tanks and is not prone to stress corrosion cracking. It is ideal for hot water tanks and drinking water pipes.

Ferritic grades have low ductility and are therefore generally not suitable for load-bearing applications. They are also magnetic, unlike austenitic grades. In some uses the difference in surface finish may be a significant factor as cold-rolled ferritic stainless steel has a slight shiny blue coloration, while austenitic grades appear gray.

Specialist advice is available

In some cases, it can be possible to make an almost direct swap to a low or no nickel grade. However, to ensure total success, Outokumpu’s experts are on hand to advise on the optimum grade as well as how to best use it, for example in adjusting forming processes.

Furthermore, the ubiquity of Core 304 and Supra 316L means that they are widely available from manufacturers and stockholders in almost any format, including hot- and cold-rolled coil, strip and plate, precision strip, quarto plate, bar, wire rod and semi-finished long products. Alternative grades do not always offer the same range of formats. However, Outokumpu will be able to ensure the best match of grade and format for your application.