Ajankohtaista toimitusketjusta

3.12.2024 Blogi: Toimittajien vastuullisuuden varmistaminen on keskeistä Outokummulle

7.11.2023 Outokumpu ja CRONIMET lisäävät yhteistyötä kiihdyttääkseen kiertotaloutta ja varmistaakseen korkealaatuisen kierrätysteräksen saatavuuden lähellä Outokummun Euroopan toimipaikkoja

6.10.2023 Outokumpu allekirjoittaa aiesopimuksen kanadalaisen Greenland Resources Inc:in kanssa vahvistaakseen vastuullisen molybdeenin toimitusketjua tulevaisuudessa

30.5.2023 Outokumpu ostaa osuuden kanadalaisesta FPX Nickel -yhtiöstä tavoitteena vahvistaa vastuullisen nikkelin tulevaisuuden oimitusketjua

16.12.2022 Raaka-ainetoimittajien vaatimukset julkaistu

1.11.2022 Outokumpu vieraili toimittajien luona Kolumbiassa

20.7.2022 Outokummun toimittajien toimintaohje on julkaistu

24.5.2022 Outokummun ihmisoikeuspolitiikka on julkaistu

4.5.2022 Guatemalalaisen toimittajan arviointi on päättynyt – tilaukset edelleen pysäytetty

6.3.2022 Outokumpu toimii määrätietoisesti Guatemalaan liittyvien syytösten noustua esiin, uudet tilaukset Guatemalasta pysäytetty

25.2.2022 Tietoa Outokummun ihmisoikeusvaikutuksista julkaistu

31.1.2022 Vierailu Onca Puman kaivokselle Brasiliassa

29.10.2021 Vastuullisen hankinnan aloite raaka-ainehankinnassa

27.8.2021 Päivitetty Modern Slavery Statement julkaistu

4.6.2021 Outokummun toimittajavaatimukset on päivitetty

10.5.2021 Outokummun toimintaohje päivitetty – Koko henkilöstö koulutetaan

6.5.2021 Outokummun tavoitteeksi vastuullisuuden edelläkävijyys: Aiempaa vaativampi ilmastotavoite ja ESG-asioiden neuvottelukunta

25.3.2021 Outokumpu kehittää toimittajiensa valvontaa ja ostojensa läpinäkyvyyttä

12.3.2021 Tutustu Outokummun toimittajien itsearviointilomakkeeseen

23.2.2021 Outokummun vastine Finnwatchin raporttiin

23.2.2021 Lehdistötiedote: Outokumpu edellyttää kaikilta kumppaneiltaan vastuullisuutta

Maailmanlaajuiset toiminnot, paikalliset toimittajat

Outokummussa hankinnat on jaettu yleisiin hankintoihin ja raaka-ainehankintoihin. Raaka-aineita ovat kaikki valmistamamme ruostumattoman teräksen ainesosat. Yleiset hankinnat vastaavat kaikista muista tuotantoyksiköiden ja muiden toimipaikkojen hankinnoista.

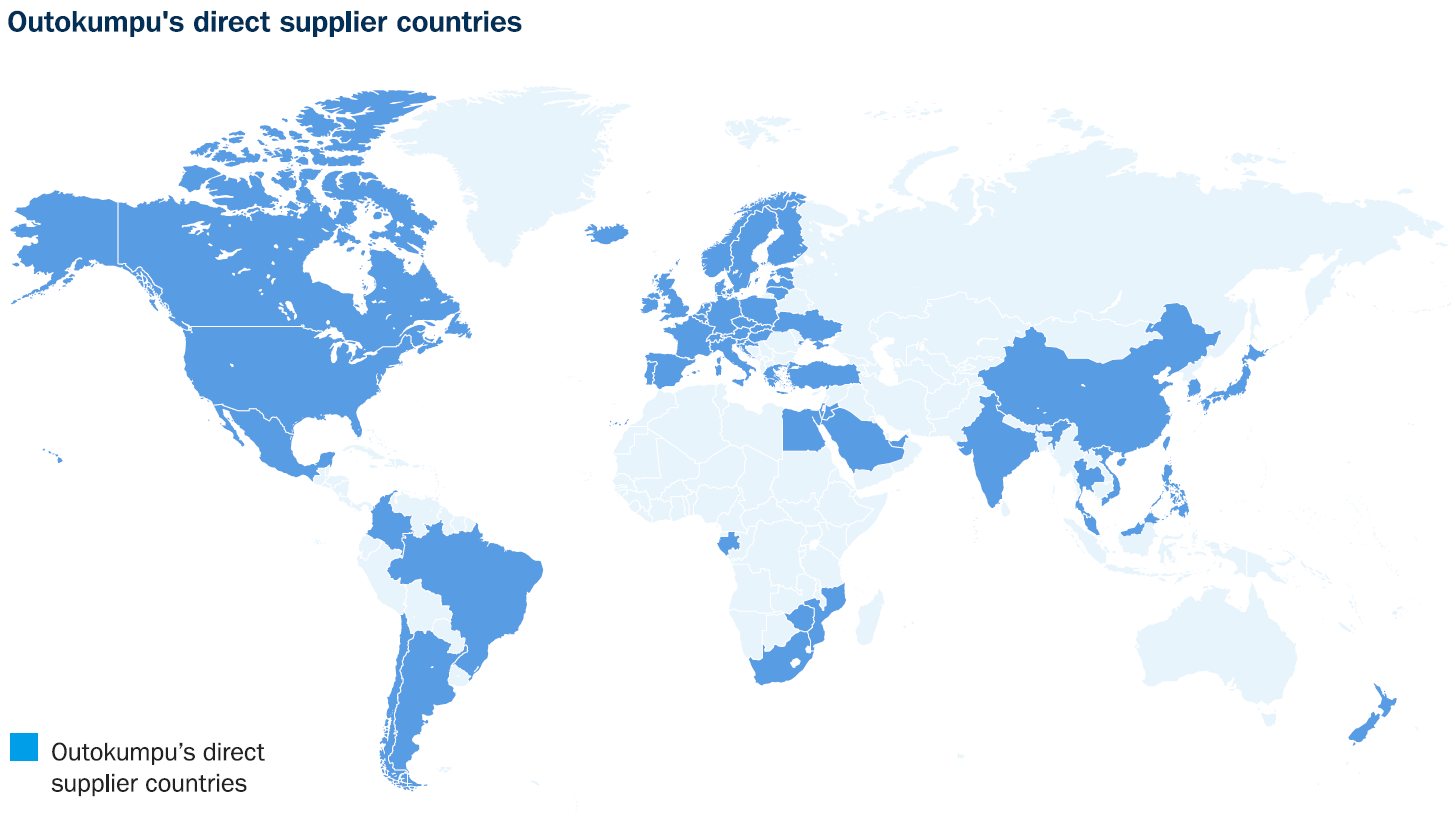

Vuonna 2023 Outokummulla oli

- Yli 7 400 toimittajaa ympäri maailmaa – paikallisten toimittajien osuus oli noin 64 % hankinnoista

- Suoria toimittajia 58 maassa

Outokummun suorat toimittajamaat 2023

Outokummun toimittajavaatimukset

Asiakkaamme vaativat meiltä paljon toimittajana, joten asetamme samat vaatimukset myös itsellemme ja omille toimittajillemme.

Työtämme toimitusketjun parissa ohjaavat konsernin toimintaohje, toimittajavaatimukset sekä yritysvastuupolitiikka. Outokumpu on myös sitoutunut noudattamaan Ison-Britannian Modern Slavery Act -lainsäädäntöä.

Kaikkien Outokummun toimittajien tulee sitoutua toimimaan seuraavien vaatimusten mukaisesti:

- Toimittajien toimintaohje: Kaikkien toimittajien ja alihankkijoiden on noudatettava toimittajia koskevaa toimintaohjettamme tai vastaavia standardeja.

- Toimittajavaatimukset raaka-ainetoimittajille ja yleisen hankinnan toimittajille: Toimittajien on noudettava soveltuvia lakeja ja säädöksiä. Outokummun toimittajavaatimukset asettavat vähimmäiskriteerit kestävälle kehitykselle ja eettisille periaatteille, työturvallisuudelle, ympäristöasioille, laadunhallinnalle, raaka-aineiden ja tuotannon hallinnalle, tuotevastuuseen, taloustietoihin, immateriaalioikeuksille, luottamuksellisuudelle ja turvallisuudelle, auditoinneille sekä liiketoimintakontakteille.

- Laadunhallintajärjestelmä: Toimittajien on ylläpidettävä laadunhallintajärjestelmää.

- Raaka-aineiden ja tuotannon hallinta: Toimittajien on selkeästi määriteltävä, dokumentoitava ja käytävä läpi omat prosessinsa, joihin kuuluu myös käytettyjen raaka-aineiden jäljitettävyys.

- Outokummun yleiset sopimusehdot

Otamme huomioon OECD:n vastuullisen toimitusketjun due diligence -ohjeistuksen. Lisäksi olemme ryhtyneet selvittämään YK:n yrityksiä ja ihmisoikeuksia koskevien ohjaavien periaatteiden sisällyttämistä tavarantoimittajille asettamiimme vaatimuksiin.

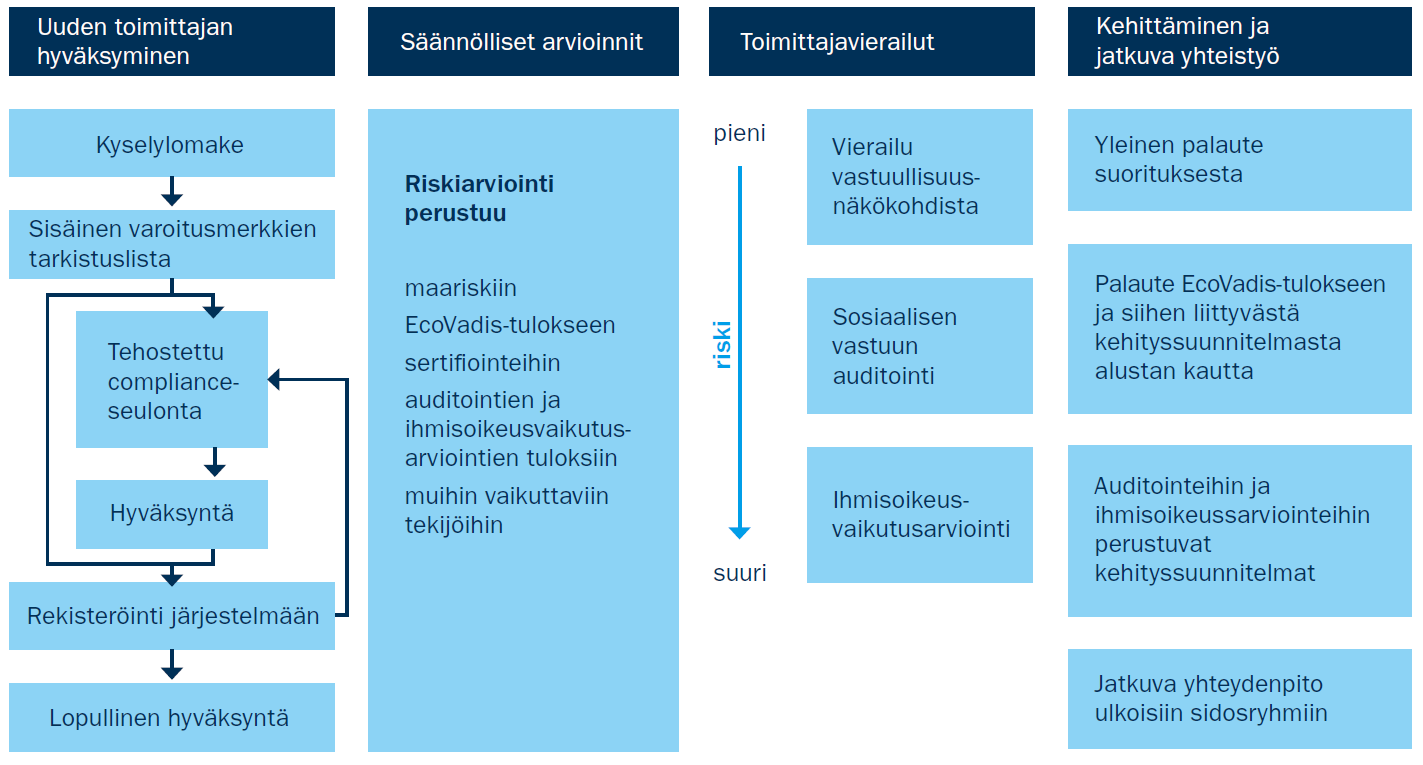

Toimittajien vastuullisuutta valvotaan

Outokumpu soveltaa riskiperusteista lähestymistapaa toimittajien valvonnassa. Toimittajan on arvioitava, ennen kuin toimittaja voidaan hyväksyä ja lisätä Outokummun toimittajaksi. Arviointiprosessissa mahdolliset riskit ja/tai mahdollisuudet tunnistetaan ja arvioidaan. Tämä varmistaa, että toimittajat noudattavat Outokummun toimittajavaatimuksia ja voivat tarjota vaatimustenmukaisia raaka-aineita, tuotteita tai palveluita johdonmukaisesti.

Outokumpu valvoo toimittajiaan itsearvioinneilla, seuloilla ja auditoinneilla. Suurin osa toimittajista käy läpi myös kuukausittaisen sanktiotarkastuksen. Raaka-aineiden hankinnassa käytetään EcoVadis-tietokantaa itsearviointeihin, jotka keskittyvät ympäristöön, työelämään ja ihmisoikeuksiin, etiikkaan ja kestävään hankintaan. Yleisissä hankinnoissa käytetyssä toimittajien suorituskyvyn arviointikyselyssä toimittajia arvioidaan seuraavilla kriteereillä: teknologia, laatu, toimitus, kustannukset, turvallisuus, ympäristö ja taloudellinen riski. Itsearviointien tuloksena parannusmahdollisuudet ja -vaatimukset voidaan tunnistaa ja sopia toimittajien kanssa.

Raaka-ainetoimittajia arvioidaan EcoVadis-tulosten ja maariskin lisäksi myös mm. saatavilla olevien sertifiointien ja aiempien tarkastustulosten perusteella. Näiden indikaattoreiden perusteella valitaan raaka-ainetoimittajat paikan päällä suoritettaviin arviointeihin. Arvioinnit vaihtelevat käynneistä tarkastukseen ja ihmisoikeusvaikutusten arviointiin riippuen havaitusta riskistä. Alla oleva kaavio kuvaa prosessia yksityiskohtaisemmin. Lisätietoja toimittajavierailuista englanninkielisellä Site Visits -sivulla.

Toimitusketjua koskevat palautteet

Outokummussa on käytössä raportointikanava väärinkäytösepäilyihin. SpeakUp-kanavassa voi raportoida myös toimittajia koskevista epäilyksistä.

Yhteystiedot

Heidi Peltonen

Vastuullisuusjohtaja

Anna Vainikainen

Head of Human Rights

anna.vainikainen@outokumpu.com

Hannah Stratmann

Head of Supplier Sustainability

hannah.stratmann@outokumpu.com